My workshop

My workshop at home is as big as a workshop in an appartment could be. Naturally, my workshop keeps on expanding as time goes by and more specialized tools are joining the club.

Big inspiration for tools and their arrangement is Adam Savage his workshop and Alexandre Chappel.

When your workshop is also your living room, it is important to keep everything stored away efficiently and cleanly. Right now, most of my small inventory is stored in 3 IKEA Helmer drawers. One of these 6-layer drawers is being divided even more by filling them up with a grid-spaced 3D-printed box system, holding all the

The majority of the tools are used for digital prototyping. A wood or metal workshop is out of reach at this moment due to lack of space.

Two modified Ender 3 printers are hanging on the wall and have become 2 very different printers over time. One can do flexibles and accuracy, the other can do speed. The Ender V2 is mostly original, but has a full-metal hotend consisting of a Bimetal Copperhead CE heat break, steel heater block, reduced dual-gear bowden drive. The Ender 3 Pro is heavily modified to a MicroSwiss hotend in Direct Drive setup, Petsfang cooling ducting and is running a custom fork of Marlin 2.0 on a Bigtreetech MiniV3 motherboard.

Besides these two FDM machines, there's also the Anycubic Photon S SLA-DLP LCD printer, including a separate alcohol wash and UV curing station. This printer produces extremely high resolution and uniform part properties.

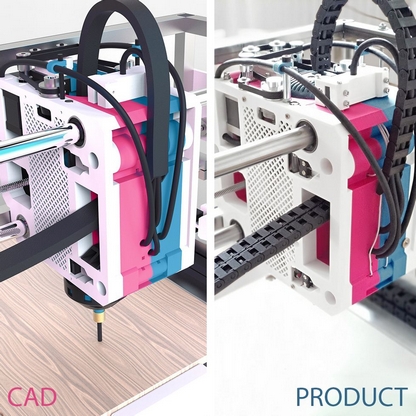

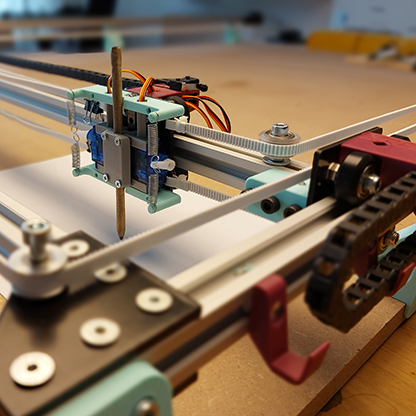

Before Elon Musk talked about 'building the machine that makes the machines', there was the RepRap project. 3D printers that could almost entirely replicate their own parts by printing them. Personally, I really enjoy making machines. It's my goal to keep a good balance between making custom parts, buying high-end stock components for crucial areas and using low-cost materials for the rest. This way, you can easily create machines that allow you to make parts or process materials you never could use before. Making machines 'unlocks' a limited workspace until you hit a new barrier. Right now, I'm working on a complex DIY 3D printer to add to my collection and I'd love to make a lasercutting module for one of my current machines in the near future.

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)