Competences

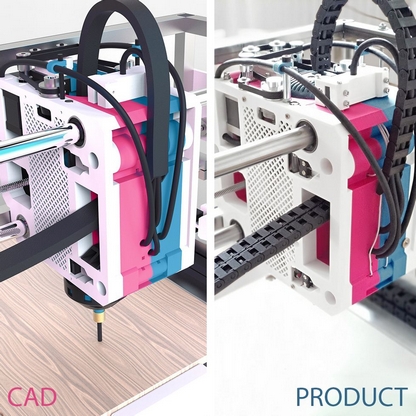

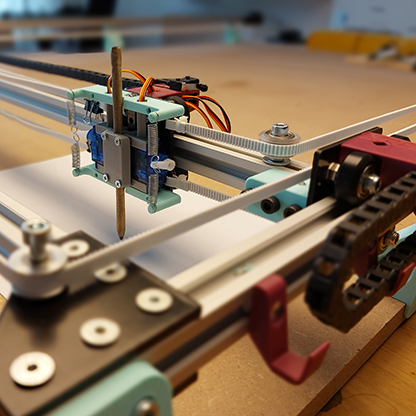

Prototyping

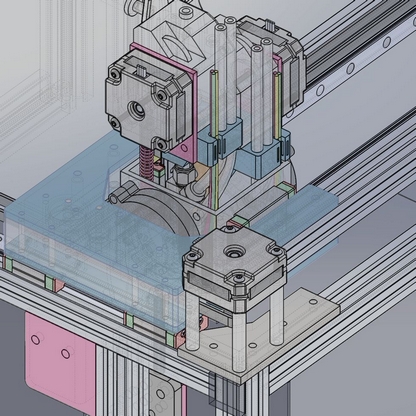

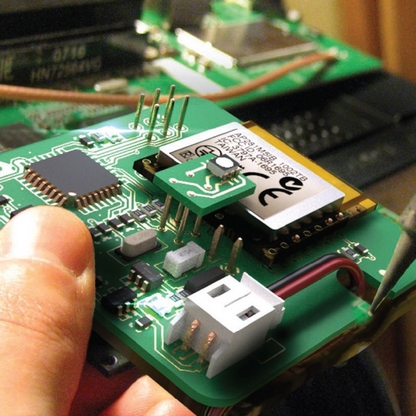

I am at my best when I can make my ideas tangible. I prefer small-scale manufacturing with digital production.

- 3D printing in-house

- Crafting

- Electronics

- Programming

- Mouldmaking

Product development

The whole product development process needs creativity. From a conceptual level to defining production details.

- Idea generation

- Product drawings

- From concept to production

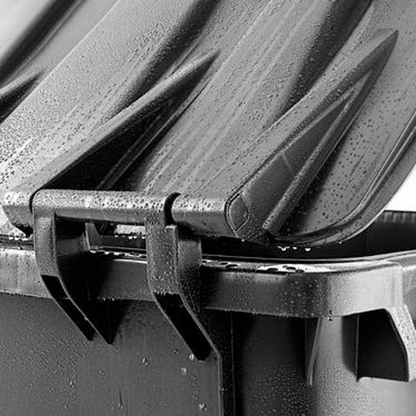

- Design for manufacturing; Injection moulding

- Design for (dis)assembly

3D Modeling

Currently I feel most comfortable drawing in SolidWorks, Rhino-Grasshopper and Siemens NX. I've used Autodesk Fusion and Inventor as well.

- Parametric solid and surface modeling

- Generative design

- 3D scanning and reverse engineering

- Top-down or bottom-up modeling

Resume

Summary

Stefan van Seggelen

Leiden, the Netherlands

1990

Digital craftsman. I develop products from first sketch to first out of tool. I love using different digital techniques in new product development, like 3D scanning, parametric/algoritmic modeling models and prototyping to accomplish clever, sustainable designs.

stefan@stefanvanseggelen.comEducation

Industrial Design Engineering

Delft University of Technology

MSc Integrated product design & BSc IDE

2008 - 2015

Graduated my MSc Cum Laude in 2015. Electives in plastic manufacturing, CAD, materials and webdesign. Minor in 'Advanced Prototyping' Electives in software and cross-cultural design.

TU Delft - IPD Master's ProgrammeProfessional experience

Product development engineer seating

Koninklijke Ahrend, Amsterdam

2018 - Present

I develop new (and optimize previous), industrial, innovative chairs for the Ahrend group which are well producable, marketable, and profitable. I keep track of the function, design, ergonomics, enviroment, strength & stiffness, safety and cost price. Ahrend chairs are targeted for offices, schools, public spaces and lounge areas.

Visit Ahrend.comProject engineer

BPO, Delft

2016 - 2018

I developed lightweight, innovative, new, high end plastic products for industries as consumer goods, industrial products, logistics and automotive for clients all around the world. At BPO, i was involved in every stage of the design process; idea sketching, working principles design, CAD, modelmaking, detailed development, design for production. I turned feedback from topology analysists, FEM-engineers and moldflow specialist into new geometry.

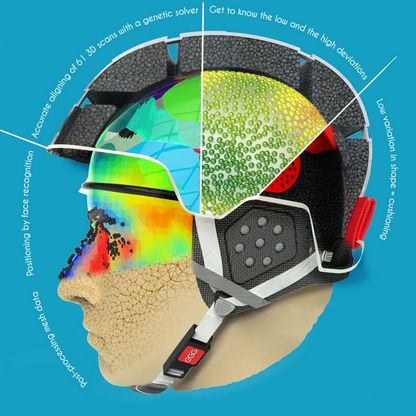

Visit BPO.nlGraduate intern

EGG Helmets, Amsterdam

2015

Master thesis topic: Designing a multi-sports helmet based on 3D ergonomic data. For EGG, i develop a new, adult-sized helmet concept with a strong accent on a marketable, realistic and producable product. With the viewpoint of the departments Design Engineering and Applied Ergonomics & Design in mind, an approach has been developed to find the optimal fitting helmet shape for a large target group. I developed a low-key algorithm in Rhino-Grasshopper that turned various 3D head scan data into an ultimate shape that fits the majority well.

Visit EGGhelmets.comBoard member and bodywork engineer @ Forze Hydrogen Racing

Forze Hydrogen Racing Team, Delft

2011 - 2013

I built the bodywork of 2 hydrogen-electric fuel cell racing cars; The Forze V and VI. The cars were being designed, financed, built and tested in the timespan of just one year. Within my function as board member, I was responsibile for delivering a good looking, aerodynamic car body. This was achieved by managing the workforce, consisting of a team of collegue part-time students of various studies, companies and institutions.

Visit Forze-Delft.nl